Sustainable cushions

With our lovely range of handmade cushions, you can now complete your interior decorating in a modern and planet friendly manner. Our cushions are also suitable for the outdoors as they are hard wearing, easily washable, UV and stain resistant.

Warm and cozy blankets made from Recycled Plastic bottles

Our blanket designs are characterized by geometric patterns. Soft and warm, it's hard to believe that these beautiful blankets are woven from recycled plastic bottles.

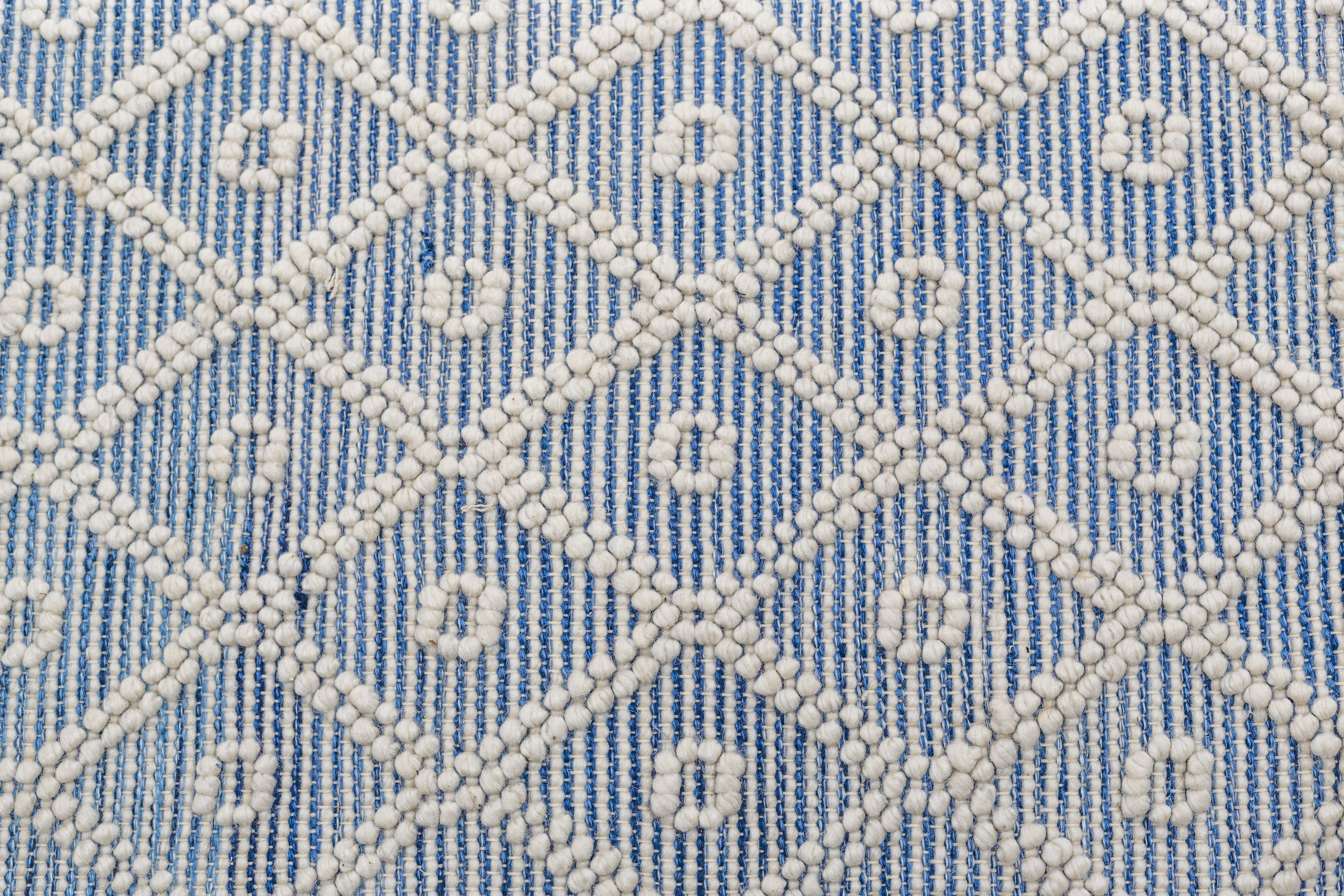

From Plastic bottles to beautiful hand woven rugs

Classic, modern and elegant. You can now decorate your household in an environmentally friendly manner with our lovely hand woven runners. Whether they are in the living room, dining room, entrance hall or bedroom - we offer high quality runner rugs that look and feel like wool. Completely made from recycled plastic bottles, our carpets are easy to clean, dust resistant and extremely durable.

Sustainable Table Runners and Tablecloths

Our sustainable table linen is made completely from recycled plastic bottles. With a classic French stripe look, the runners and tablecloths are rustic and timeless, and look and feel like linen.

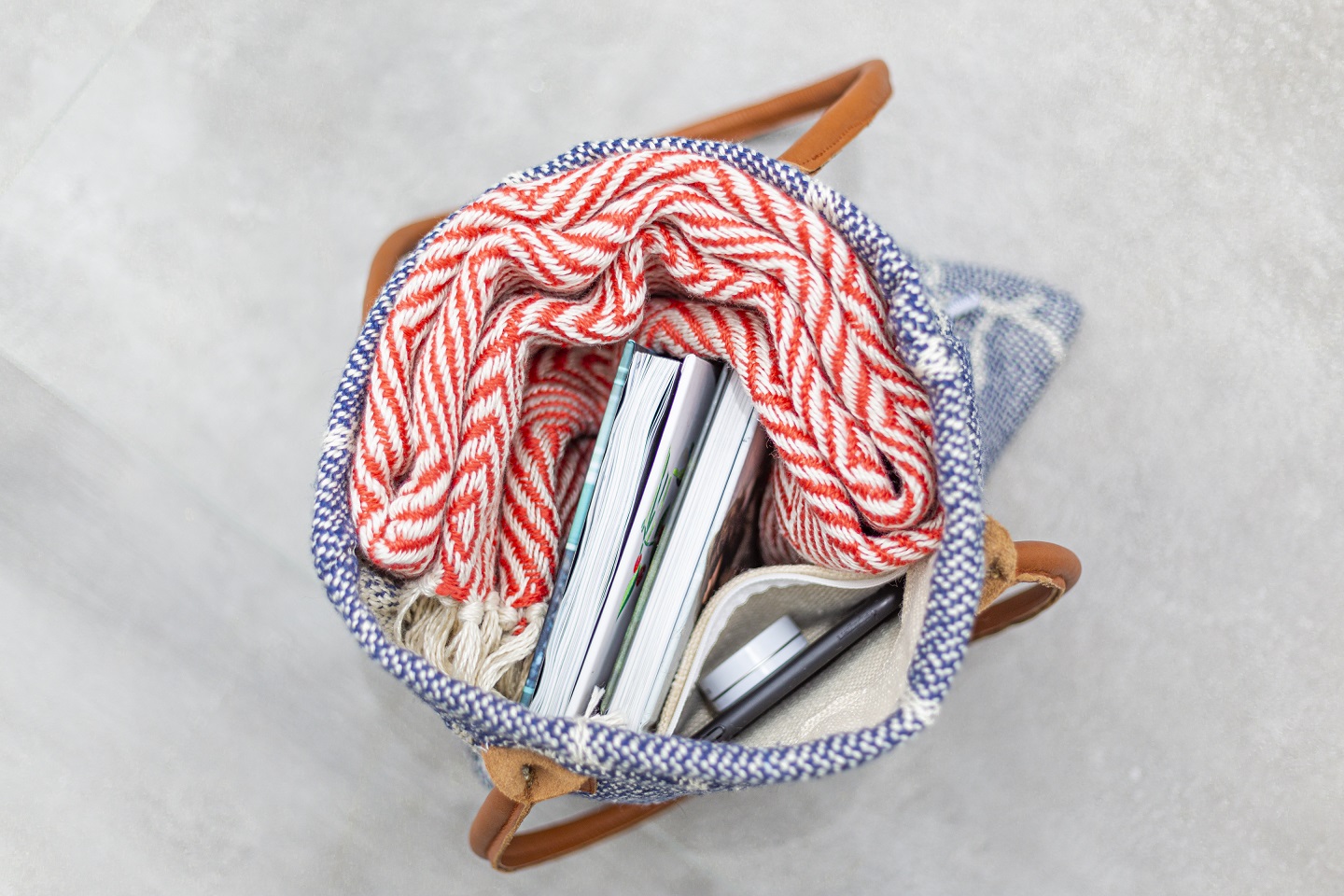

Tote bags for everyday use, that remove plastic waste from our environment & plant trees

Practical tote bags made completely from recycled plastic bottles allow you to complete your look in an environmentally friendly manner. With leather handles, these bags are perfect for laptops, groceries and all items you need with you when you're on the go.

Hi everyone, I'm Kirsty. I'm originally from South Africa and currently live in Germany. The whole concept of recycling, separating waste etc. was a totally new topic for me that I only really discovered here in Europe. After having a baby, I was fortunate enough to have some parental time off from my 9-5 job. Being outdoors a lot I started noticing the amount of litter lying around. This was especially apparent to me when we visited my family in South Africa and on travels. While completing one of my training dives for my PADI certification, I was stunned to see how many bottles and tins were scattered on our beautiful ocean floor, disturbing our ecosystems.

With the time off work, I started reading a lot about recycling and especially re-use of plastic waste. I watched documentaries about our planet and how the plastic waste in oceans disturbs our eco systems. I researched statistics about plastic waste and was shocked to see and understand how much waste we as humans create. For a long time, I was occupied with the thought that there must be ways we can use this plastic waste for long term benefits. I soon discovered the many ways plastic bottles can be recycled and reused. Who would have thought that PET bottles, discarded as litter, and which have ended up in our oceans and environment, could be recycled into strong yarns and can be woven and used to create beautiful home accessories.

Interior decorating has always been a passion of mine. I love to decorate rooms and make our home feel like a cozy home. Blankets and pillows in matching colour hues and complimentary patterns are not only practical accessories, but also allow you to make bold statements with individual style or just simply add elegance to your home.

I love the products we offer at Eco Inner Living. They have all been individually hand crafted by skilled artisans and their texture and quality makes it really hard to believe that these items are made from recycled plastic bottles. They look and feel like wool products, are durable but most importantly, sustainable products. By buying our products, you are removing plastic waste from our oceans and environment and this allow you to clean up the Planet from your living room.